Auto Viscosity controller with data communication iCom (centralized control / centralized management)

Automatic ink viscosity controller Data communication system ” iCom ”

catalog available in Japanese/English/Chinese Part 1

Charles Darwin

It is not the strongest of the species that survives,

nor the most intelligent that survives.

It is the one that is most adaptable to change.

by Charles Darwin

The above words are said to be the famous words of Charles Darwin

in England, which is famous scientist for evolution.

This word is a famous word that are quoted by many business books.

It was also a word that always came to my mind

when I was thinking about marketing, product development,

and the direction of the company management.

if we look around the world and the environment around us,

we understand well.

looking at the social environment from my childhood

to the present,

i think that what exists and remains now are industries that respond to social changes, things that respond to changes in the times, systems, and companies.

Japan scenery in 1970′ in Tokyo

It is the present, 50 years later from my childhood,

there are still companies that respond to changes in the 50-year era,

and companies that respond to future changes.

I think it is also the nature of many companies and people

to resist responding to the changing times, even though there are examples around us that are easy to understand.

I, myself also often find myself unconsciously resisting the changes

of the times.

An introduction became long.

The Flexible packaging industry, including gravure printing,

flexo printing, dry lamination, and so on,

where we work, of course, is not immune to changes in the times.

A big trend is environmental issues.

In addition to VOC regulations,

the world is at the helm of tackling climate change.

As usual, it starts from Europe.

Realization of a carbon-neutral,

zero-greenhouse gas emissions decarbonization society.

Japan’s Prime Minister Mr. Naoto Kan has also said

he will achieve carbon neutrality in 2050.

Japan is keeping up with the changes in the world.

I think our industry will also be forced to change in a variety of ways,

including reducing CO2 emissions, condescension,

utilization of recycled energy, thorough VOC regulations, water-based inks,

and recyclable substrates (films).

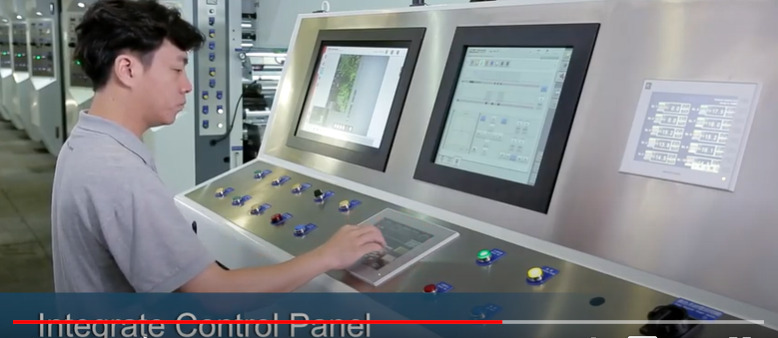

Likewise, Industry 4.0 is again coming from Europe.

Realization of smart factories,

digitization of production and distribution processes.

Utilization of big data that gathers various related data,

AI (artificial intelligence).

In order to achieve these,

the first assumption is the centralization of information

(centralized management, centralized control).

I think these are the main things that are looming over our industry.

It was also something that I felt while working at previous company

before I started Viscon (Japan) Corp. in 2014.

I strongly felt that the viscosity controller which i was selling

was not responding to the change in the flow of the times,

compared to gravure printing machines, inspection equipment,

and colorcon (regesration machine), which are rapidly evolving

with the times.

Considering with a time span of 10, 20, or 30 years,

and we can look at it and thought about it.

if we look at this kind of thing in a short span of about a year or two,

it’s hard to understand.

even as the demands on print quality from clients

are constantly becoming more severe with the times,

only my selling viscosity controller do not communicate the viscosity controller’s operating information as data, and are outside the data processing of gravure printing machine

and inspection macine and colorcon.

Only the viscosity controller alone was used by the customer only ” memory ’’ in the operator’s head.

Is viscosity management related to improving the quality

of customers’ gravure printing?

Of course, Yes !!

When I started selling viscosity controllers overseas at my previous company,

I started explaining to overseas customers

because of the need for viscosity management.

(Not like Japan, viscosity controllers are not popular overseas,

and it was essential to explain the necessity of viscosity management

in order to improve the quality of gravure printing.)

About half of the items related to poor gravure printing

require viscosity management and ink management.

(viscosity management system).

I will also write a separate article in this English blog

about this in the future.

There is no way that Japanese operators using viscosity controllers

do not know about this.

So why is the viscosity controller not the only one doing

data communication management (centralized management

and centralized control of viscosity information )?

The answer was not because of the user side conditions,

but because of the manufacturer side of the viscosity controller,

that is, due to the machine side conditions of the viscosity controller.

From the conclusion, I explain,

1. Manufacturers of viscosity controllers have not been developing

viscosity controllers with standard data communication functions

required for viscosity management.

So-called centralized management and centralized control of

viscosity information.

Centralized control, centralized management

is system that is required in Europe and the United States.

(Some manufacturers in Japan have produced viscosity controllers

with communication functions, but users have pointed out

that there is a problem with convenience to use for gravure printing

machines 8-color machines and 10-color machines.) processing, etc.

when moving viscosity controller from some unit to other unit.

In addition, because the price is extreamly high,

users’ willingness to invest does not spring. )

2. Using a conventional viscosity controller, the phenomenon that the

viscosity display data swings up and down was often seen.

in addition, there were many breakdowns.

it was also well seen that accuracy was lacking with time.

It is easy to understand this when thinking about using the car as an example.

Let’s say you’re driving on a highway with a speed limit of 80 kilometers.

Naturally, we drive so as not to exceed the speed of the car over 80 km.

In fact, how do we do it?

We are looking at the speedometer display of the car,

and we are looking at the number 80 kilometers on speedometer displaying.

that is,

the speed of the car we are actually driving = speedometer display

If we write something like this, you might get scolded

for what we are doing for granted.

Yes, the actual speed = the speedometer display is running reliably,

so the display of the speedometer is reliable and can be utilized.

(believe in the speedometer display and can use the data)

This is a natural thing.

the displaying number, figure of the display counter of the viscosity

controller swings up and down greatly.

if you apply to the example of the car above,

by car on the highway (even if we are actually driving at 80 km speed),

the speedometer speed display shows

70 km, ????

90 km, ????

80 km, ????

as you say, if you see speedometer number (figure) different from

the actual speed of the car,

you can’t use the speedometer of the car,

and no one can drive a car like this.

the actual speed ≠ the display of the meter.

the actual viscosity ≠ the display of viscosity controller

In fact, what was natural at viscosity controller display showing was

that the actual true viscosity of liquid was not displayed.

That’s why users of viscosity controllers were also in trouble.

Speaking of viscosity controllers,

I do not think that the user can utilize the data communicated

from the viscosity controller like that.

Therefore, from the user’s point of view, it was concluded,

there is no meaning and no reliable if use such a viscosity controller

that does not display the actual liquid viscosity.

This is happening from because the communicated viscosity data itself is

not reliable viscosity information or viscosity data.

Why viscosity controller can not display true and reliable figure comes from

the technological and machinery problems,

such as insufficient cleaning of the viscosity controller

and poor lubrication.

reference : material customer dissatisfaction, troubles, and inconvenience to viscosity controller

if you refer to the above material,

it is clear that the viscosity controller was insufficiently cleaned

and the lubrication failure was reducing the accuracy of the viscosity controller.

The cause of item 3 in the above article is analyzed for poor accuracy and the display number swinging up and down.

Insufficient cleaning of the diaphragm pump and worn out of the pump parts due to poor lubrication have destabilized the pulsation of

the diaphragm pump, and the unstable pulsation has caused

the display to display unstable numbers and figures.

if these problems (oil-free generation due to insufficient cleaning and lubrication failure) are not solved by Viscon (Japan) Corp, it is not possible to utilize the viscosity data communication function that is the change of

the ” era ”.

i

Like Charles Darwin’s famous words,

” conventional viscosity controllers were not ready for changes in the world.”

it can be said.

Viscon (Japan) Corp. which is familiar with the principle of viscosity controllers,

succeeded in developing a viscosity controller

that responds to this ” change in the era from the company beginning

and foundation.

Viscon Japan auto ink viscosity controller for gravure printing, for Flexo printing, for Dry lamination and for coating machine.

Viscon Japan Corp. development concept at the of founding

1. Development of viscosity controllers to meet the ” changing of era ”.

That is, the viscosity controller with viscosity management data

communication function is guaranteed not to cause failure of

the viscosity controller due to insufficient cleaning or lubrication failure,

or a decrease in the accuracy of the viscosity controller.

Providing users with trusted and reliable data,

Viscon (Japan) Corp. come true that users can have centralized control,

centralized management of viscosity data.

2. We worked on technology development to solve these problems and

developed patented technologies.

Insufficient Cleaning problem → development of a cleaning method

called TURBO WASH with

strong bubble cleaning (patent)

Lubrication defect problem → smart lubrication system

development of lubrication system

called no require priming pump work

(patent)

Since both of these development technologies have been granted as

official patents after filing and examination patents, Viscon Japan

viscosity controllers can be objectively defined as changing from

conventional viscosity controllers.

Viscon Japan auto ink viscosity controller equipped with

the above-mentioned Viscon Japan patented technology enables

quality control in response to the change of the era where

customers can obtain reliable viscosity management data

(centralized management and centralized control).

Viscon Japan auto ink viscosity controller has already been in development

and release of patented technology for 7 years in Japan, Asia countries,

USA, Middle East and Africa.

It is also evaluated by customers as a patented technology that is

“worth more than the price”.

Only with reliable viscosity data,

traceability of highly accurate QC management can be performed.

This is a catalog of iCom system for auto ink viscosity controller

with viscosity data communication function of Viscon Japan Corp.

Viscon Japan data communication system iCom catalog English

click below. 👇 👇

Catalog data Viscon Japan data communication system iCom English

Viscon Japan data communication system iCom catalog Chinese

click below. 👇 👇

Catalog data Viscon Japan data communication system iCom Chinese

👉 👉 to be continued

Auto Viscosity controller with data communication iCom

( Centralized control / Centralized management ) Part 2

If any questions or unclear things,

please do not hesitate to contact us Viscon Japan Corporation. 👇 👇

コメント