Auto Viscosity controller with data communication iCom (centralized control / centralized management)

Automatic ink viscosity controller Data communication system ” iCom ”

catalog available in Japanese/English/Chinese Part 2

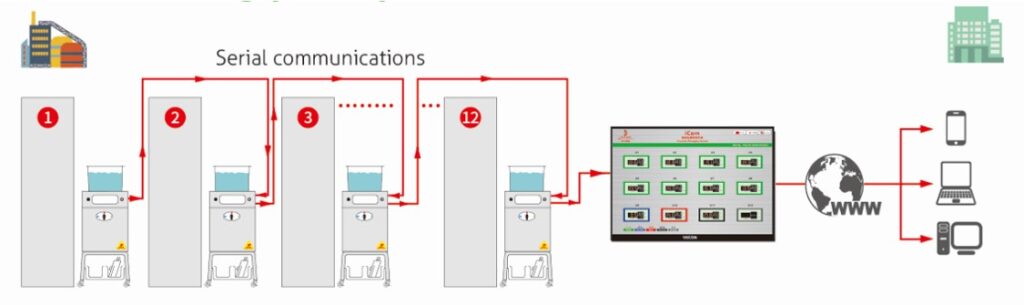

iCom viscosity controller, developed by Viscon Japan Corporation, features reliable viscosity management data communication capabilities.

In the previous concerned blog article Part 1,

it was explained that while various components in the printing industry,

such as gravure printing machines, inspection machine, and color controllers,

had adopted data communication (centralized management and control), viscosity controllers had not followed suit.

The reason for this lag was not on the user side

but rather on the side of the manufacturers of viscosity controllers,

who were unable to advance in this direction.

Viscon Japan patent technology, “Turbo wash ” and ” Smart Lubrication system” solved users’ problems.

Data communication (centralized management and control) requires

presence of viscosity controllers that can accurately display the true

viscosity of liquid agents.

Without the emergence of such viscosity controllers,

data communication (centralized management and control)

would be meaningless.

The factor that was hindering the accurate display of data has been resolved through Viscon Japan’s patented technology.

Therefore, viscosity controller with reliable viscosity data communication functionality that customers have been eagerly awaiting can be realized through the centralized management and control of viscosity information, thanks to Viscon Japan’s patented technology.

For users, the needs and wants they desire in a viscosity controller

with data communication functionality

(centralized management and control) are as follows :

1. Reliable viscosity management data is communicated.

2. For use with 8-color and 10-color gravure printing machines,

the viscosity controller should facilitate easy adjustments

when it is moved.

For example, when a viscosity controller was used with printing

unit No. 4 in the current printing, it should be simple to switch

it to printing unit No. 5 for the next job.

3. The design should be versatile to accommodate various applications.

For example as bellow.

3-1 Installed on gravure printing machines from printing machine

manufacturers.

(So far, we have worked with 8 printing machine manufacturers

in Japan, Taiwan, and China.)

YouTube Video

(Centralized Control of Viscosity Information Installed

on Printing Machines)

Please click ↓↓

IPF Online Expo – Worldly

E.L.S High Speed Rotogravure Printing Machine – YouTube

In the promotional video of Worldly Industrial’s gravure printing

machine, Viscon Japan data communication-enabled viscosity

controller system, iCom, is installed and featured as

“Monitoring Viscosity.”

(Starting from 2 minutes and 23 seconds into the video).

3-2 Customers purchase the data communication-enabled Viscon Japan

iCom viscosity controller, and their in-house engineers handle

the installation and design of data processing for traceability

on their own, connecting it to touch panels, computers,

and other systems.

Here is an example of the monitoring design of the Viscon Japan

viscosity controller with data communication-enabled iCom system

that was connected and designed by Japanese customer in-house.

↓↓ by Japanese customer in-house desisn

(This Japanese customer is using the iCom system for data communication,

centralized management, and centralized control of their dry lamination.)

3-3 Viscon Japan has prepared these as ready-made models:

the data communication-enabled viscosity controller iCom

and a touchscreen panel (for list display settings and traceability

data utilization on a computer).

(The overseas models have been developed and delivered to customers.

The Japanese market model is currently in preparation and is

expected to be developed and released within this year.)

3-4 R&D Collaboration between Taiyo Electric Industry Co.,Ltd.

and Viscon Japan Corporation.

” Colorcon Collabo “ so-called.

Viscon Japan’s data communication-enabled iCom viscosity controller

compatible program is included in Taiyo Electric Industry

Co., Ltd.’s models:

・ SKT-001

・ DT-3000

・ Model LC+

For users purchasing the above models from Taiyo Electric Industry

Co., Ltd., it is convenient and cost-effective to introduce Viscon

Japan’s data communication-enabled viscosity controller iCom

at the time of purchase.

The same applies when upgrading the register controller

(Colorcon).

4. For customers like the ones mentioned above,

Viscon Japan Corporation offers an economical system that provides

accurate viscosity information through data communication features,

ensuring convenience for various applications without incurring high

investment costs.

(Note: From Japanese customers who have adopted Viscon Japan

Corporation’s data communication-enabled viscosity controller iCom,

we have received positive feedback regarding the system’s

convenience and its economical budget, which has been highly

appreciated by all customers.)

aiming to create a “viscosity controller that doesn’t fail” and

garnering positive feedback from customers.

(Development was completed in 2015.)

The “iCom” from Viscon Japan Corporation, along with their patented technologies “TURBO WASH” and “Smart Lubrication System,” quickly became familiar

trademarks among our customers in the world.The iCom viscosity controller from Viscon Japan Corporation is used by many

customers in Japan, China, Taiwan, the Philippines, Thailand, Malaysia,

and more, enabling accurate and convenient centralized viscosity information management and control.The following photo shows the Viscon data communication-enabled viscosity

controller iCom system used by our customer in the Philippines.

It is equipped on 10-color gravure printing machine from Worldly Industrial Co., Ltd.

in Taiwan, serving as a viscosity control system that includes viscosity management

data for centralized data management and control (centralization).

The Viscon data communication-enabled viscosity controller iCom

has cables running from the rear of the electrical room,

connecting and facilitating data communication among 10 units

Viscon data communication-enabled viscosity controllers iCom.

If any questions or unclear things,

please do not hesitate to contact us Viscon Japan Corporation. 👇 👇

コメント