Customer Feedback : The use of Turbo Wash has significantly reduced viscosity controller malfunctions.

This feedback comes from Viscon users in Japan, Taiwan, Thailand, the Philippines, Singapore, Malaysia, Indonesia, Vietnam, and Bangladesh.

“Actions speak louder than words.”

“Seeing is believing.” Part 1

Due to Covid-19 pandemic, I was compelled to return to Japan,

which led to a significant change in my lifestyle.

Prior to this, I used to travel to around 13 countries,

including China and Japan, where our agent and users were based,

almost every month, from Shanghai in China.

This pattern shifted dramatically over the last three and a half years.

Two and a half months ago, I embarked on my first overseas trip

since the pandemic, which took me to Thailand for the Open House

and the Propak Asia 2023 exhibition.

Unable to travel abroad and facing significant restrictions even within Japan,

I found myself in what felt like a “confinement” in Japan (laughs).

This situation prompted me to channel my energy into activities

like creating content for social media platforms like SNS, YouTube,

Facebook, as well as producing content for the company’s official blog

in both Japanese and English versions, as I couldn’t enjoy the freedom

of movement both internationally and domestically.

Gathering information from platforms like YouTube on my own,

I took about two and a half years to go from server subscriptions

to launching a blog.

Looking back now, I realize that without covid-19 pandemic,

I might not have been able to realize these endeavors yet.

Although our blog (in both Japanese and English) is humble,

it appears to have been viewed by people from 35 countries around

the world, including Japan.

This includes individuals from countries where our Viscon Japan brand

viscosity controllers have not yet been introduced.

Below is the list of countries where Viscon Japan viscosity controllers

have not been introduced yet, but people from these countries

have accessed our blog (in both Japanese and English versions).

( Ireland, the UK, Germany, Switzerland, Norway, Finland,

Italy, Spain, Yemen, Brazil, Canada )

Once again, I have come to truly appreciate the power of the internet.

We have been utilizing our blog and YouTube to provide convenience

not only to customers who are already using our Viscon viscosity controllers

but also to receive positive feedback from overseas customers

about the convenience and good service it offers.

Both YouTube and the explanations in this blog post have been used as references by our customers and agent distributors.

In the future, such convenient utilization is expected to further expand

among our distributors and users.

With this direction in mind, we plan to prepare and publish articles that

are conscious of such purposes.

Articles that align with such goals are the focus of this topic.

“Viscon Japan Revolutionized the History (Common Sense) of

Viscosity Controllers in 2015,”

as said by customers from various Asian countries.

Customers were led to say such things due to the following elements:

- New development in cleaning method – Turbo Wash (Patented)

- No need for air purging, Smart Lubrication System (Patented)

- User-friendly structural design (Industry-first)

the proliferation of cleaning functions began in the market.

This led to the standardization of stainless steel solvent tanks

and set the current market standard, all initiated by

Viscon Japan viscosity controllers.

For details and an overview of Turbo Wash, please refer to the following blog article when you have the time.

Related Reference Blog Post ↓ ↓ Please click.

引用記事url

In this related blog post, we explain the motivation behind our development of Turbo Wash and provide an overview of its features.

Now, it’s all well and good to have developed something new,

but the real question is:

how does it perform in actual use?

This is crucial, both for us as manufacturers

and for the customers and users who will be using it.

Actions speak louder than words.

Seeing is believing.

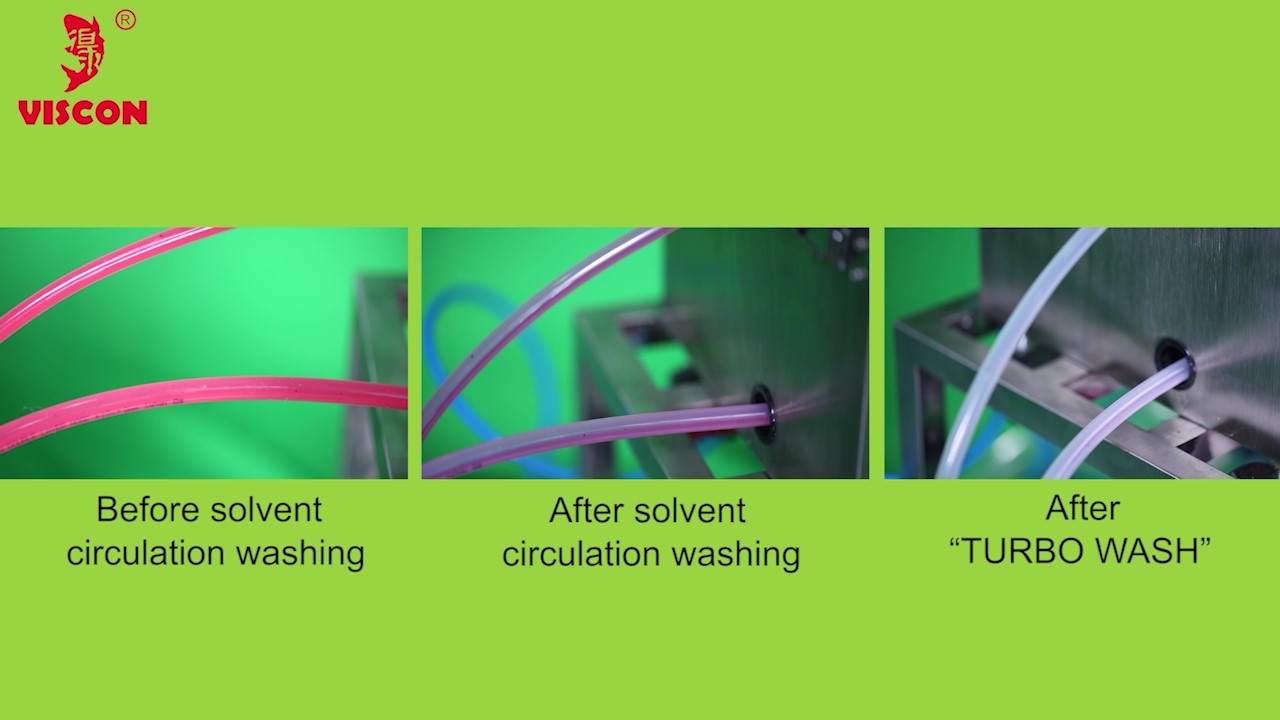

The superior cleaning capability of Turbo Wash compared to

traditional solvent circulation is clearly demonstrated in

the experiment data provided in the aforementioned related blog post.

The real question is how actual customers and users who have used it

found the performance.

Please refer to this photo. (Actions speak louder than words.

Seeing is believing.)

Information about this customer is explained in the following blog post

for your reference. Philippines customer.

Related Reference Blog Post ↓ ↓ Please click.

引用 URL

Within this related article, the background, circumstances, and details

about this customer in the photograph are thoroughly explained.

Please take the time to view it when you can.

Viscon Japan patent technology, “Turbo wash ” and ” Smart Lubrication system” solved users’ problems.

Actions speak louder than words

Seeing is believing – A picture is worth a thousand words.

❶ The customer arranged the Turbo Wash-equipped Viscon Japan

viscosity controller and another brand’s viscosity controller

(which I sold during my previous job, around 30 units)

alternately in each unit of the gravure printing press.

Turbo Wash-equipped viscosity controller

+

Conventional viscosity controller

+

Turbo Wash-equipped viscosity controller

❷ Why?

Why did the customer arrange them in this way?

➌ Answer: The conventional viscosity controller does not have

the powerful bubble cleaning of Turbo Wash.

With the traditional solvent circulation cleaning,

the cleaning is insufficient → Leading to malfunctions.

Therefore, even when cleaning the conventional viscosity controller,

the adjacent Turbo Wash-equipped viscosity controller (Viscon Japan)

with Turbo Wash is used to achieve thorough cleaning.

This is why the customer arranged them in this way,

using the Turbo Wash-equipped viscosity controller from Viscon Japan

to fully experience the superior cleaning ability.

memo

Subsequently, the president of this customer in the Philippines

arranged the viscosity controllers, alternating between Viscon Japan’s

viscosity controller and another conventional one, as shown in the photo.

They conducted Turbo Wash cleaning for all the viscosity controllers.

㋐ As a natural outcome, Viscon Japan’s viscosity controller

experienced no malfunctions, and the previously frequent malfunctions

in the other conventional viscosity controllers also drastically reduced.

㋑ Furthermore, they started using Turbo Wash for cleaning

the circulation pumps used in the factory.

㋒ The result was a significant reduction in malfunctions for the other conventional viscosity controllers and also a substantial decrease

in circulation pump malfunctions.

㋓ Consequently, overall malfunctions were greatly reduced,

leading to a substantial decrease in expenses for purchasing

spare parts.

memo xxx

Turbo Wash の YouTube ビデオ

↓↓ クリックして下さい

Turbo Wash YouTube video

30th-anniversary party, and I received gratitude from the president of

this company in Philippines.

(See the photo below, this company’s 30th Anniversary Party)

Traditional Viscosity Controller:

3 Major Causes of Malfunction | Viscon Japan’s Solutions

① Inadequate Cleaning: 50% – Turbo Wash (Patented)

② Insufficient Lubrication: 30% – Smart Lubrication System (Patented)

③ Improper Operation: 20% – User-Friendly Design

3 Major Causes of Malfunction in Conventional Viscosity Controllers: as noted above.

These are the findings drawn from the extensive repair experience of our Chief Development Officer, often referred to as the “Viscometer Doctor,” who has over 23 years of history in the viscosity controller field. Additionally, these conclusions are supported by my marketing analysis. These causes highlight the persistent issues associated with traditional diaphragm pump viscosity controllers.

Based on this root cause analysis, the necessity for new research and development for enhancing customer convenience became evident. As a result, new technologies were developed by Viscon Japan Inc., which are the aforementioned solutions:

- TURBO WASH

- Smart Oil Injection System

- User-Friendly Design

These innovations directly address the issues identified and bring about advancements in the field of viscosity control.

If any questions or unclear things,

please do not hesitate to contact us Viscon Japan Corporation. 👇 👇

コメント