40 Thailand Open house held at Shrinkflex

Featuring exhibition of Viscon Japan iCom viscosity controller

Date: June 13, 2023

Exhibition Propak Asia 2023

Date : June 14 – June 17 2023

Place : Bitec Bangkok , Thailand

Booth : AG29 Webcontrol Machinery Co.,Ltd.

Due to the COVID-19 pandemic, my activities have been limited to

within Japan for approximately three and a half years.

This business trip to Thailand is my first overseas trip since returning

to Japan from Shanghai in January 2020, where I participated in

Convertech Japan 2020 exhibition.

For the past 40 years, I have been stationed overseas (in the Netherlands

and China) and had frequent business trips abroad, almost every month. Therefore, going three and a half years without a single overseas trip was

highly unusual for me, even among the exceptional moments in those years.

As a result, preparing for this trip to Thailand felt somewhat unsettling

and unfamiliar.

Not having traveled abroad for such a long time had even affected

my instincts, making me feel a bit off-kilter.

However, once I boarded the plane from Chubu Centrair International Airport

and met Michael, General Manager of Shrinkflex in Thailand, at our usual meeting spot in Bangkok Airport, all the three and a half years of hiatus vanished in an instant. I quickly returned to my usual self, as if nothing had changed.

This business trip to Thailand has two main events.

The first one is the Open House at Shrinkflex Thailand, where our Viscon Japan centralized control iCom viscosity controller is being showcased.

20 units of viscosity controller are in operation,

along with one unit dedicated for the dry laminator.

It provides an opportunity for numerous customers from various countries

to witness the actual operation status of Viscon Japan iCom viscosity controller.

The second event is our participation at the Propak Asia 2023 exhibition, where we are exhibiting with Webcontrol Machinery at their booth.

Our viscosity controllers from Viscon Japan are being showcased by our

Thailand agent Cheong Ming Co., Ltd.(led by President Michael). As this is an exhibition, it will run for four days from the 14th to the 17th.

Now, for the first main event, the Open House.

Participants gathered at the hotel for registration and check-in starting

from 8 a.m.

We all boarded a prepared tour bus and set off towards Shrinkflex Company.

The bus journey took approximately one hour.

Here is the schedule for the Open House on the day:

The participants were from Thailand, Japan, Taiwan, Vietnam, Malaysia, Indonesia, and Singapore.

Representatives from Viscon Japan’s overseas agents also attended,

coming from Thailand, Malaysia, Indonesia, and Vietnam.

The program was packed with content, and we had plenty of time to visit the factory inside.

We enjoyed a delicious lunch prepared inside the factory, which truly showcased Michael’s excellent taste.

The expressions on all the participants’ faces were of satisfaction.

Open House schedule

The initial schedule had the following speeches planned

from 10:00 AM to 11:30 AM:

- Shrinkflex : Mr. Michael, General Manager

- Webcontrol Machinery : Mr. Ali, General Manager

- Viscon Japan : Mr. Matsuoka, President

- KV-Swiss : Mr. Gianfranco, General Manager

However, on the day of the event, there were some last-minute changes,

and the speeches for items 2, 3, and 4 were replaced with

a presentation from HP, a digital printing machine manufacturer.

The speech content I had prepared was not used during the presentation. However, during the factory tour on the event day,

the participants had the opportunity to witness the effective performance of Viscon Japan’s communication-based iCom viscosity controllers,

with a total of 20 units installed on two lines of 10-color gravure printing machines.

Additionally, they could see the smooth operation of Viscon Japan’s viscosity controllers, benefiting from Turbo Wash, on the dry laminator without any issues.

These practical demonstrations of Viscon Japan’s viscosity controllers served

as a strong testament and effectively conveyed the appeal of our products

to the attendees, acting as a substitute for my speech.

I will post the speech content from the event day here, which proved to be helpful in answering questions from participants during lunch, breaks,

and the evening dinner.

I hope it can be a useful reference for all of you.

Viscon Japan auto ink viscosity controller for gravure printing, for Flexo printing, for Dry lamination and for coating machine.

Scheduled Speech Content – Manuscript and Voice Output

I have attempted to generate the voice output for the above speech content.

I have attempted to generate the voice output for the above speech content.You can listen to it here.

It showcases the advancements in technology.

We took a group photo at the end with participants from Thailand, Japan, Taiwan, Malaysia, Vietnam, Indonesia, and Singapore.

Everyone expressed their thoughts, saying that today was truly a meaningful

day at the Open House.

Afterwards, everyone boarded the sightseeing bus and headed to

the dinner venue, a restaurant on the way to the hotel in Bangkok.

Since Shrinkflex, the host of the Open House, is a publicly listed company

in the Thai stock market, their internal management is well-maintained.

Taking photos and making notes inside the factory were strictly prohibited,

and bringing smartphones or other devices was also not allowed.

Due to these circumstances, the photos that can be posted on this blog

are limited.

The second main event, the Propak Asia 2023 exhibition,

As soon as you entered the exhibition venue at BITEC,

there was an early announcement of next year’s schedule.

Propak Asia 2024 is scheduled to take place from June 12th to 15th.

This was my fourth time participating in the exhibition at BITEC.

Over the past four years during the COVID-19 pandemic,

the floor layout had changed compared to before.

The current layout concentrated the exhibition spaces,

making it more convenient than before.

Both exhibitors and visitors who attended the exhibition,

as well as industry-related machinery and equipment manufacturers,

were unanimous in saying,

“Propak Asia 2023 was truly a great success this year.”

I also agree it !!

Due to the COVID-19 pandemic, I hadn’t been able to meet many of

our customers and industry-related machinery and equipment manufacturers

for the past three years.

During this exhibition, I found myself engrossed in conversations with them

at our booth and elsewhere, and I actually forgot to take many photos.

Well, I guess I was just caught up in the discussions!

I also forgot to ask others at the booth to take photos while I was engaged in business discussions.

Perhaps this lapse was due to the three-year gap caused by the pandemic.

I will reflect on this.

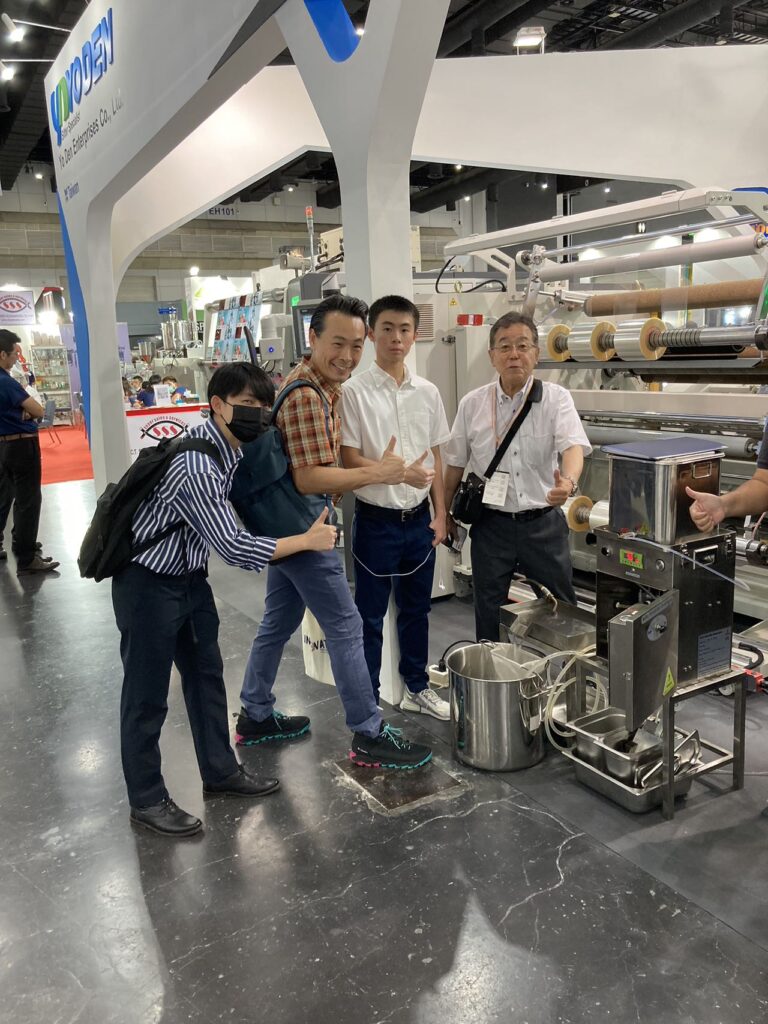

Towards the end of the third day of the exhibition,

I realized that I didn’t have any photos, so I took the opportunity to take a picture as a commemoration.

There was a customer from Indonesia who uses Viscon Japan’s viscosity controller, so I thought it would be nice to have a photo together.

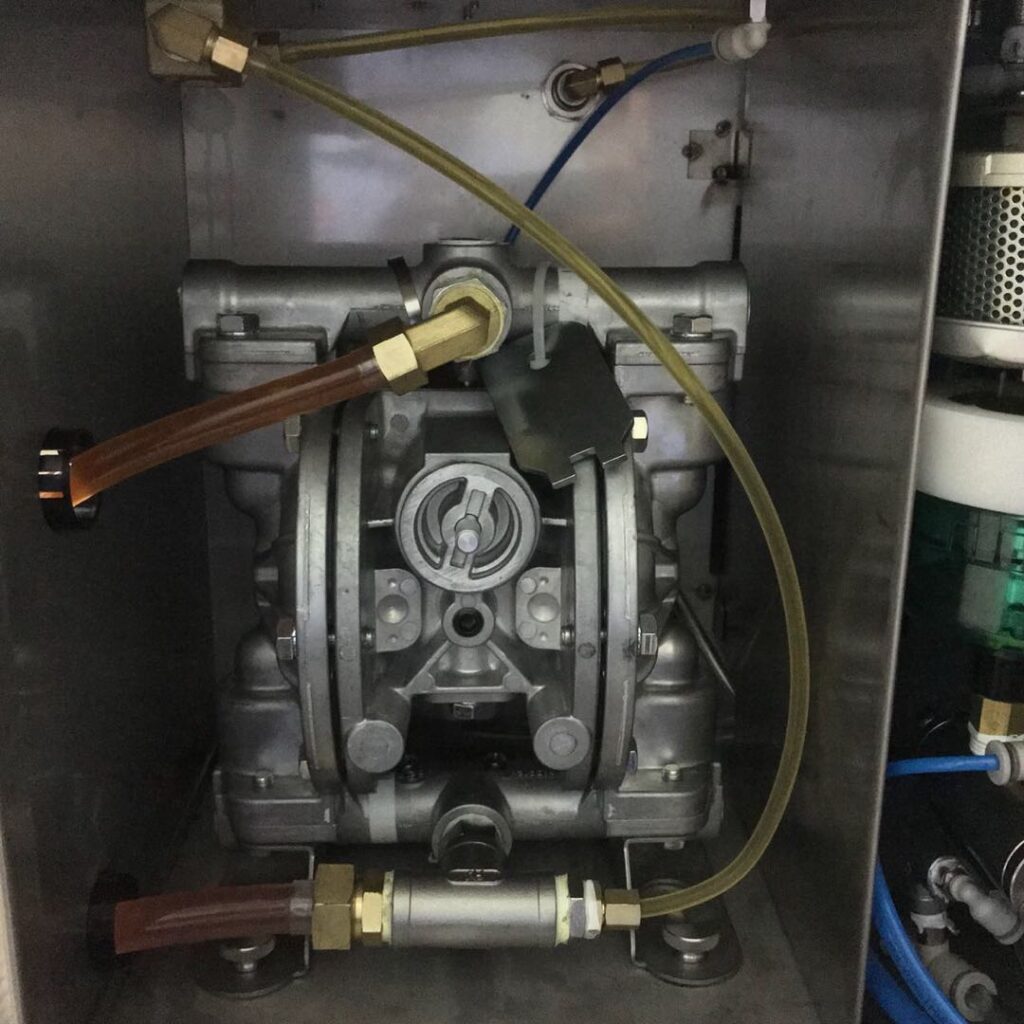

We were grateful to have Yamada Corporation, who supplies the heart of Viscon Japan’s viscosity controllers, the “diaphragm pump,” represented by the Managing Director and staff of their Thailand subsidiary, Yamada (Thailand) Co., Ltd., at the exhibition.

Prior to attending this exhibition, a study session on viscosity controllers

had been organized within their company, and they came to the exhibition venue.

At the exhibition, with the actual viscosity controllers in front of them,

there were enthusiastic inquiries from them, and my explanations to them

came naturally and with great enthusiasm.

The aforementioned viscosity controller is equipped with 10 types of

diaphragm pumps from Yamada Corporation.

In 2017, Yamada Corporation and our company, Viscon Japan, collaborated to release a viscosity controller with 15 types of diaphragm pumps.

The model name of our viscosity controller is VIS-15eco.

The VIS-15eco, which is our model of viscosity controller, is an eco-friendly version that achieves the same performance and capability as the conventional 15 types of diaphragm pumps while reducing air consumption by 20% compared to the previous consumption.

It is an environmentally friendly diaphragm pump that contributes to energy efficiency and CO2 reduction.

We are grateful for the development of a diaphragm pump that is truly

filled with improvements, maintaining the same level of performance

as the previous model without any reduction in capability.

Not only does it achieve a 20% reduction in energy consumption,

but it also exhibits reduced pulsation, a characteristic of diaphragm pumps, compared to the previous model.

We truly appreciate the efforts made to create such an enhanced

diaphragm pump.

If any questions or unclear things,

please do not hesitate to contact us Viscon Japan Corporation. 👇 👇

コメント