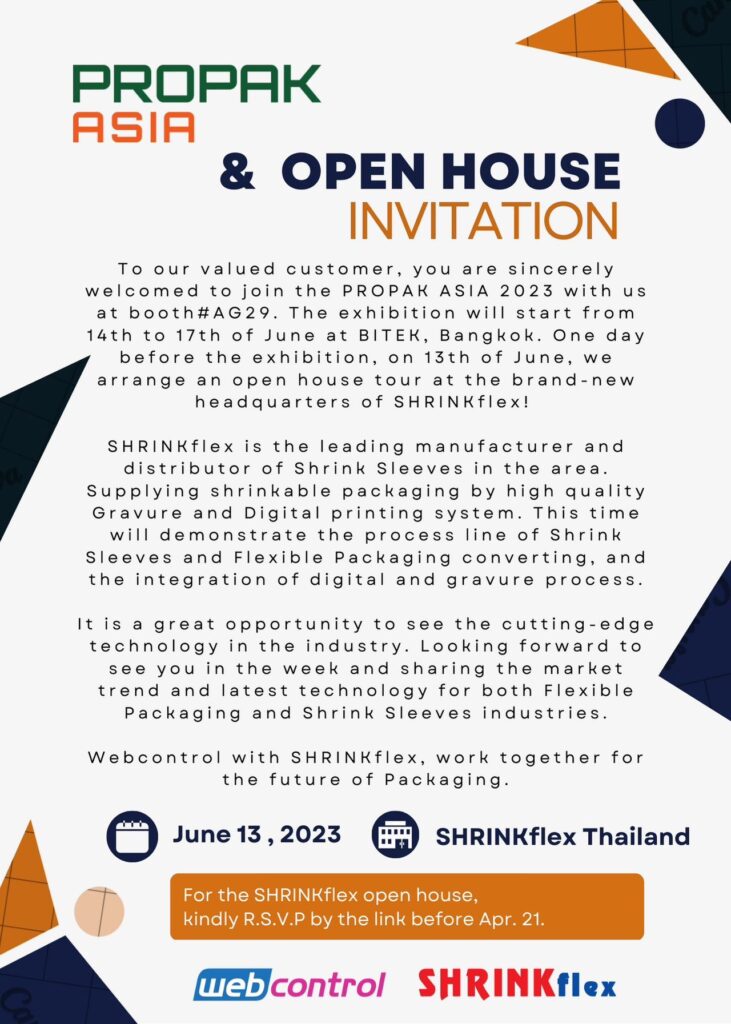

Exhibit at Propak Asia 2023 in Thailand.

In addition, will be hosting an Open House

on the day before Propack Asia 2023.

Open House

Day & Time : June 13, 2023 10:00 – 17:00

Place : Shrinkflex Thailand Co.,Ltd.

Machinery : Webcontrol Machinery Gravure press 10color x 2 line

Viscon Japan iCom viscosity controller x 20 units

Others Dry Laminator, Inspection machine, etc.Propak Asia 2023 (Exhibition)

Day & Time : June 14 ~ June 17 2023

Place : Bitec Bangkok

Booth : AG29

Company : Webcontrol Machinery Co.

Our previous exhibition of Propack Asia was Propak Asia 2019.

Now, we will be exhibiting at Propak Asia 2023.

The four-year gap between these two exhibitions truly reflects

the significant impact of the Covid-19 pandemic on countries worldwide.

It serves as a testament to the magnitude and realization of the pandemic’s effects during that period.

Finally, we are able to resume normal international business activities.

We can now travel by airplane without the need for quarantine periods

or PCR testing.

Similar to the previous Propak Asia 2019 exhibition,

we will be hosting an Open House event before the Propak Asia exhibition. At Shrinkflex Thailand, we will showcase the Gravure printing machine from Webcontrol Machinery and Viscon Japan iCom viscosity controller

with communication capabilities to the participants for Open House

Open House at Shrinkflex Thailand

of the machinery facilities, focusing on Webcontrol’s gravure printing machine, dry lamination machine, and other equipment.In addition, visitors will have the opportunity to explore peripheral equipment, including defect inspection machines and Viscon Japan

iCom viscosity controllers.ShrinkFlex, one of the organizers,

is an outstanding company that achieved a successful listing

on the Thai stock market.They made their debut on the Thai stock market in the fall of 2020. Additionally, it was a joyous year for the company as it marked the auspicious occasion of the marriage of son of Mr. Michael, the president of ShrinkFlex.

Both the left and right Webcontrol gravure printing machines are

equipped with Viscon Japan iCom viscosity controller with data communication functions.Shrinkflex has been implementing viscosity data monitoring

and digital transformation of viscosity controllers since 2018.

iCom Viscosity controller by Viscon Japan

There are four methods for implementing the iCom viscosity controller,

and in the case of ShrinkFlex, they have adopted method 1.

As method 1,Webcontrol machinery, the gravure printing machine manufacturer,has set up the iCom viscosity controller and

the connection program to the touch panel of the gravure printing machine.

This implementation method has already been widely adopted

by printing machine manufacturers in Japan, Taiwan, and China,

with proven results.

It is becoming a standard practice in the industry.

In the near future, Korean printing machine manufacturers are also expected to join and adopt this method.

The progress is underway in that direction.

Methods for implementing the iCom viscosity controller

- Through printing machine manufacturers:

The iCom viscosity controller is integrated into the printing machine’s system during the manufacturing process. This method involves collaboration with the printing machine manufacturer to ensure seamless integration and compatibility. - “Colorcon Collaboration” during Colorcon (manufactured by Taiyo Electric Industry) upgrades or newly purchasing:

When upgrading the color controller system, the iCom viscosity controller can be connected with upgrades Taiyo Electric Industry

Colorcon. - Self-setup with own touch panel:

The Users prepares its own touch panel or control system and configures the necessary connections to integrate the iCom viscosity controller. - Retrofitting the iCom viscosity controller to existing printing machines with pre-designed touch panels:

The iCom viscosity controller is installed as an additional component alongside the existing printing machine, utilizing pre-designed touch panels or control systems. This retrofitting process enables the incorporation of viscosity control functionalities into the existing printing setup.

Our Viscon Japan viscosity controller is also equipped in the dry laminator.

In the viscosity controller used in the gravure printing machine,

our patented technology, Turbo Wash, allows for a set wash time

of 5 minutes.

Viscon Japan viscosity controller for the dry laminator,

which most customers are greatly concerned about,

has Turbo Wash with a setting of 15 minutes.

Thanks to the powerful cleaning capability of Turbo Wash,

it enables the viscosity controller to operate in a significantly

more stable and reliable manner compared to conventional

viscosity controller which do not have Turbo Wash.

Customers who have actually experienced such benefits

often make a specific request when ordering viscosity controllers

for dry laminators from our company.

They emphasize the following request:

“Since it is for use in dry lamination,

please make sure to set Turbo Wash to 15 minutes.”

Many customers who use viscosity controllers for dry lamination

are genuinely troubled by issues such as clogging and reduced delivery quantity.

The conventional solvent circulation cleaning method often struggles to effectively clean the adhesive used in dry lamination.

Above are some interior photos showcasing Shrinkflex Thailand’s facilities.

Schedule for the Open House on the day:

10:00 - 11:30 SFT Company Profile の detail event

10:00-11:00SFT Company profile by Shrinkflex Thailand

Introduce Machinery Manufacture

Speaker :

Mr. Ali General Manager , Webcontrol Machinery

Mr. Matsuoka , President, Viscon (Japan) Corporation

Mr. Gianfranco. General manager ( KV-Swiss)

Speech of Mr. Matsuoka from Viscon (Japan) Corp. 👉👉 Voice Out put

Shrinkflex and Webcontrol are sending invitations to customers in Thailand, Japan, Taiwan, Malaysia, Vietnam, Indonesia, and the Philippines.

The Open House held on the day before the major exhibition called Propak Asia is an efficient and wonderful event for both the participating customers from around the world and the manufacturers exhibiting.

As equipment and machinery manufacturers, three companies are scheduled to be speakers, and Viscon Japan is one of them.

Viscon Japan auto ink viscosity controller for gravure printing, for Flexo printing, for Dry lamination and for coating machine.

Propak Asia 2023 Exhibition

At Webcontrol’s booth, our Thai agent Cheong Ming will be showcasing Viscon Japan viscosity controller.

Additionally, with the Open House being held, a collaboration project between Taio Electric Industries’ color controller and Viscon Japan iCom viscosity controller has started this year.

Therefore, not only Cheong Ming, the Thai agent,

but also the presidents of Green Express, the Indonesian agent,

Sakata Inx Vietnam, the Vietnamese agent, and Rotojaya,

the Malaysian agent, are scheduled to participate in

the exhibition in Thailand.

We are already experiencing the iCom viscosity controller being implemented in Japan, Thailand, China, Malaysia, Taiwan, and the Philippines.

The collaboration with Taio Electric Industries’ Colorcon has also begun, and we can now feel that we are entering a phase where the adoption of iCom viscosity controller will further expand in

various Asian countries.

the COVID-19 pandemic.However, I can feel everyone’s enthusiasm to unleash the “accumulated magma power” we have been gathering over these three years and channel it into our business endeavors.

Please click ↓↓ Viscon Japan YouTube

If any questions or unclear things,

please do not hesitate to contact us Viscon Japan Corporation. 👇 👇

コメント