The Working Principle of Viscosity controller

Part 1

Diaphragm pump type

Diaphragm pump not only play a roll of pump,

but also play a roll of sensor of viscosity controller.

It is amazing and convenient !!

Viscon Japan auto ink viscosity controller for gravure printing, for Flexo printing, for Dry lamination and for coating machine.

Working Principle of Viscosity controller

Diaphragm pump type

As the viscosity of the ink increases,

the pulsation of the pump slows down.

This is based on the principle of a diaphragm pump,

which is a type of viscosity controller that measures and controls

the viscosity of the ink by using the diaphragm pump

as both a pump and a viscosity sensor.

The diaphragm pump changes its pulsation frequency

according to the viscosity of the ink.

When the viscosity increases, the pulsation frequency decreases.

When the viscosity decreases, the pulsation frequency increases.

Characteristics of Diaphragm pump

Ink viscosity UP ⇒ Pulsation of pump decrease

Pump speed slow

Ink viscosity DOWN ⇒ Pulsation of pump decrease

Pump speed slow

Diaphragm pump type viscosity controller makes use of characteristics

of diaphragm pump.

Diaphragm pump plays roll of not only circulation pump,

but also viscosity measuring sensor.

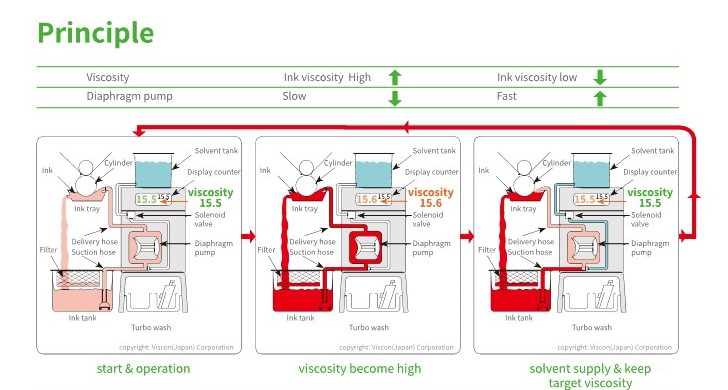

The following drawing and chart shows viscosity controll flow

by diaphragm pump type viscosity controller.

Drawing A Drawing B Drawing C

Drawing A

1. Circulation of ink with the target optimal viscosity.

2. Detection of pulsations from the diaphragm pump of the viscosity

controller, converted into cup seconds, and displayed

as numerical values on the Viscosity counter’s display.

Viscosity Values (PV) 15.5

Set values (SV) 15.5

Drawing B

1. During the printing or coating process,

viscosity increase of 0.1 cup seconds.

Viscosity Values (PV) 15.6

Set values (SV) 15.5

Drawing C

1. Solvent supply through solenoide valve opening

Viscosity Values (PV) 15.5

Set values (SV) 15.5

to maintain the target optimal viscosity.

Please refer to below drawing / chart.

Diaphragm pump type viscosity controller do not have

independent viscosity measuring sensor.

1. Diaphragm pump plays roll of not only circulation pump,

but also ” viscosity measuring sensor “.

2. Other types of viscosity controller consists of circulation pump

and viscosity measuring sensor.

3. Other types of viscosity controller should be washed and cleaned

in 2 main places, such as pump and viscosity measuring sensor.

Diaphragm pump type viscosity controller should be washed and

cleaned in 1 main place, only diaphragm pump.

This is the so strong advantage of diaphragm pump type

viscosity controller.

For all kinds and types of viscosity controller,

about 50% breakdown and failure cause is

” Not enough washing and cleaning ”

” Not enough washing and cleaning “.

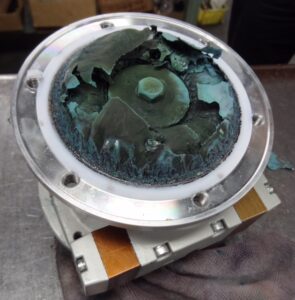

bad washing diaphragm pump

Bad washing of suction strainer

4. For users at flexible packaging industry in the world,

washing and cleaning is the biggest headache matters.

Diaphragm pump type viscosity controller reduce

washing cleaning load 50%.

This is the biggest advantage and merits for users.

Even using advantaged diaphragm pump type viscosity controller,

most of users of conventional diaphragm pump type users

were suffering from “Washing & Cleaning headache problems ”

Therefore, Viscon Japan have developed ” Turbo Wash “ which is

Japanese patent technology. ( Japan Patent No. 6421093 )

YouTube ” Turbo Wash ” ☜☜ Please click

to be continued The Principles of Viscosity controller Part 2

If any questions or unclear things,

please do not hesitate to contact us Viscon Japan Corporation. 👇 👇

コメント